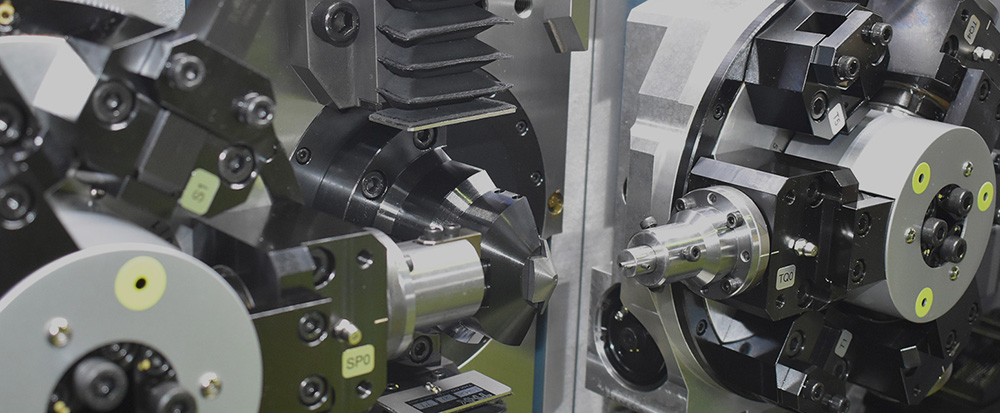

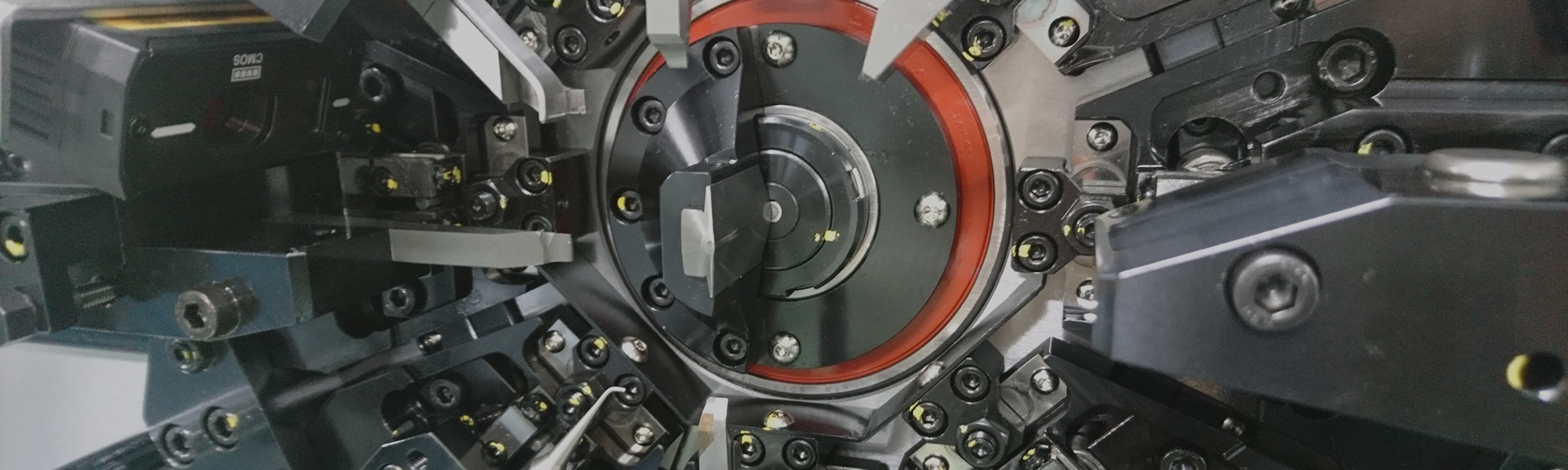

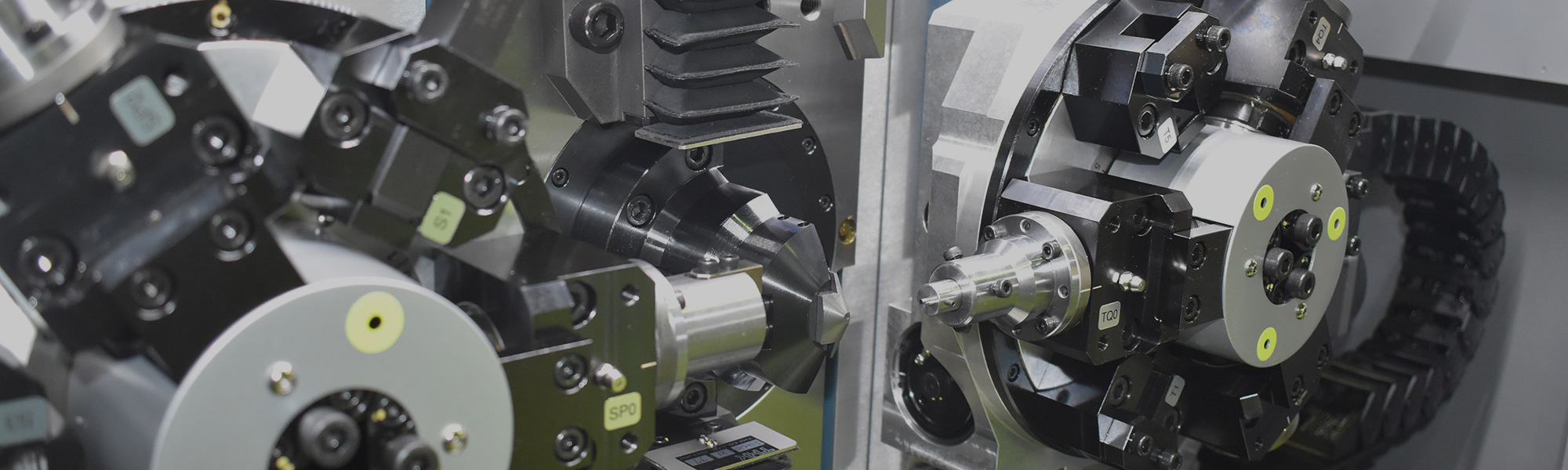

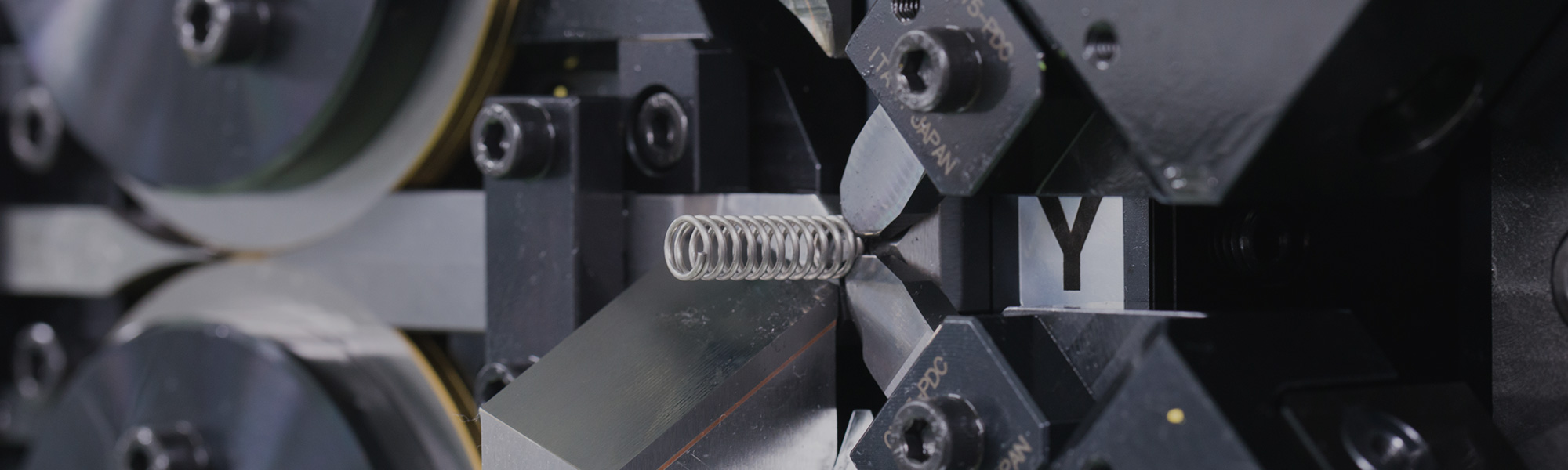

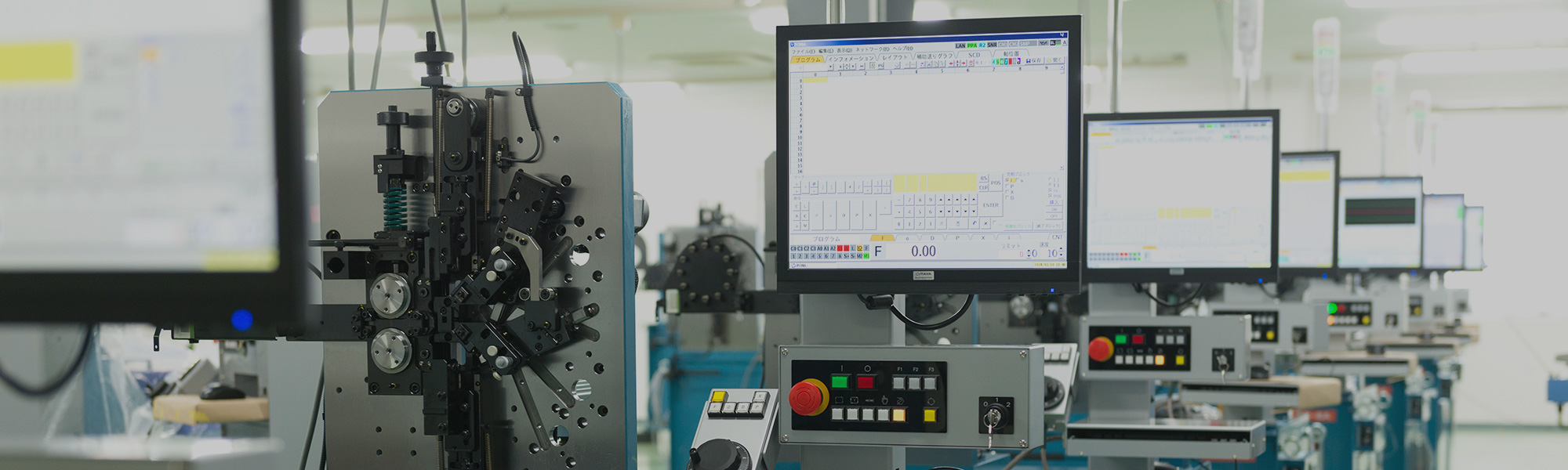

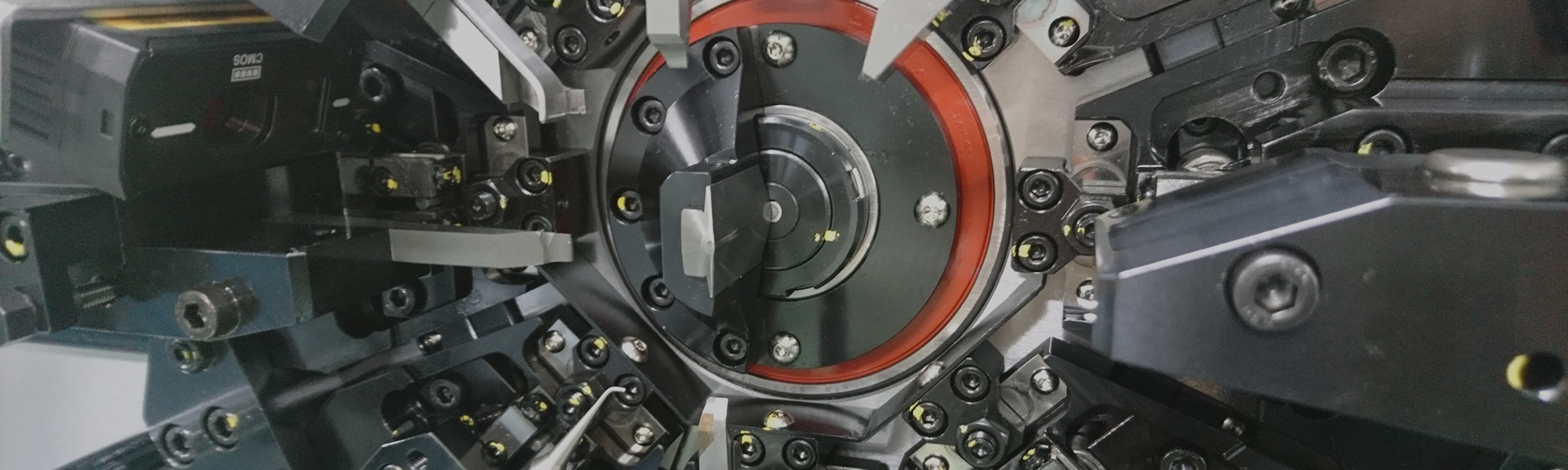

ばね成形機のパイオニア

Pioneers of spring making machinery

革新的な機械を創り出す

Creating innovative machines

私たちのゴールはお客様の成功です

Our goal is our customers’ success

100年企業に向かって

Working towards our 100-year anniversary

Apr 15,2024 ゴールデンウィーク休暇のお知らせ

Feb 01,2024 wire 2024(国際ワイヤー産業展) に出展しま…

Dec 12,2023 冬季休暇のお知らせ

Sep 20,2023 大阪プライベートショー開催のお知らせ

Aug 04,2023 夏季休暇のお知らせ